Side Plates

Core Components Kit

SKU

Name

Quantity

30525-01

Gantry Side Plate

2

Now that you’ve built the work area, we’ll guide you through the construction of the main carriages and rails of the X-Carve. We’ll start by assembling the plates and carriages of the Y and X axes, then we’ll put it all together to form the gantry.

Assemble Gantry Side Plates

The gantry side plates hold various wheels, brackets, and motors. They are joined by the main gantry rail included in your kit. There are a number of holes and slots on the plates. Below is a diagram of the plate. Note that when assembled, both plates will form mirror images of each other, though the beveled edge will always face up and towards the front of the machine with the holes for makerslide on top. We’ll start by assembling the righthand plate.

Fixed V-Wheels

Core Components Kit

SKU

Name

Quantity

25286-43

Button Head Cap Screw M5 x 25

4

25287-12

M5 Flat Washer

4

25203-01

V Wheel Assembly

4

30265-09

Nylon Insert Lock Nut M5

4

First, we’ll attach the fixed v-wheels to the carriage. Insert the M5x25 bolt into one of the smaller v-wheel holes, then put on an M5 flat washer followed by a v-wheel. Use an M5 nylon lock nut to secure the assembly. Tighten the nut until secure using a 3mm hex key on the bolt and an 8mm wrench on the nut.

Repeat this for the other v-wheel on the right-hand plate, and then repeat the process for the left hand plate on the other side. You should now have two mirrored plates that look like this:

Adjustable V-Wheels

Core Components Kit

SKU

Name

Quantity

25286-49

Button Head Cap Screw M5 x 30

4

25195-07

Short Eccentric Spacer

4

25287-12

M5 Flat Washer

4

25203-01

V Wheel Assembly

4

30265-09

Nylon Insert Lock Nut M5

4

Attaching the adjustable v-wheels is a bit more complicated, though you won’t have to adjust them until later in the assembly. These v-wheels are adjusted by means of a short eccentric spacer (25195-07) that rests inside a larger hole on the plate. By turning the spacer, the distance between the v-wheels can be adjusted just enough to make sure that they are snug on the Makerslide rail. For the moment you’ll want to install the spacers in the ‘open’ position, that is, rotated so that the adjustable v-wheel is as far from the corresponding fixed v-wheel as possible.

Begin by placing a short eccentric spacer (25195-07) on an M5x30mm bolt. Be sure that the circular part of the spacer is on the opposite side of the screw head, per the below image.

Place the screw and spacer through one of the larger holes on the side plate. Make sure that the circular part of the spacer is facing the plate and fits into the hole on the plate. Place an M5 washer and v-wheel onto the bolt.

Secure the assembly with an M5 nylon lock nut using a 3mm hex key and 8mm wrench. Make sure not to over-tighten the assembly.

Now you can repeat this for the other side of the plate. You should have two mirrored plates that look like this:

If damaged during assembly, you can find additional Dual Bearing V-Wheels in the Spare Parts Kit.

Smooth Idler Wheels

Core Components Kit

SKU

Name

Quantity

25286-49

Button Head Cap Screw M5 x 30

4

25312-23

Aluminum Spacer 5.1mm ID 9.5mm OD 9.5mm LG

4

30265-09

Nylon Insert Lock Nut M5

4

9mm Belt and Motor Kit

SKU

Name

Quantity

25197-10

Smooth Idler Pulley Assembly

4

25287-13

M5 Flat Washer

8

These wheels ensure that the belt is held tightly against the motor pulley once they are installed. They are installed with aluminum spacers as they need to be aligned with the center of the Makerslide rails. We show both wheels being attached at once for illustrative purposes, though as long as they’re in the right places, assemble them in whichever order you want.

To attach the smooth idler wheels, begin by putting an M5x30 bolt through the appropriate hole on the plate. Slide an aluminum spacer onto the bolt.

Place an idler wheel onto each bolt. Make sure that the side of the wheel with the recessed bearing is facing away from the plate.

Add two M5 washers to on top of each wheel.

Thread an M5 nylon lock nut onto each bolt and secure with a 3mm hex key and 8mm wrench. The nut isn’t the most accessible with the flange of the idler wheel in the way, so you may have to angle the wrench.

Repeat this for the other plate. You should now have two mirrored plates that look like this:

Stepper Motors

9mm Belt and Motor Kit

SKU

Name

Quantity

25311-10

Stepper Motor - NEMA 23

2

In this step, we’ll be attaching the motors to the Y plates. The motor pulleys are already attached to the shafts of the motors so you won’t have to worry about attaching or adjusting them.

Core Components Kit

SKU

Name

Quantity

25285-52

Socket Head Screw M5 x 16

8

30265-09

Nylon Insert Lock Nut M5

8

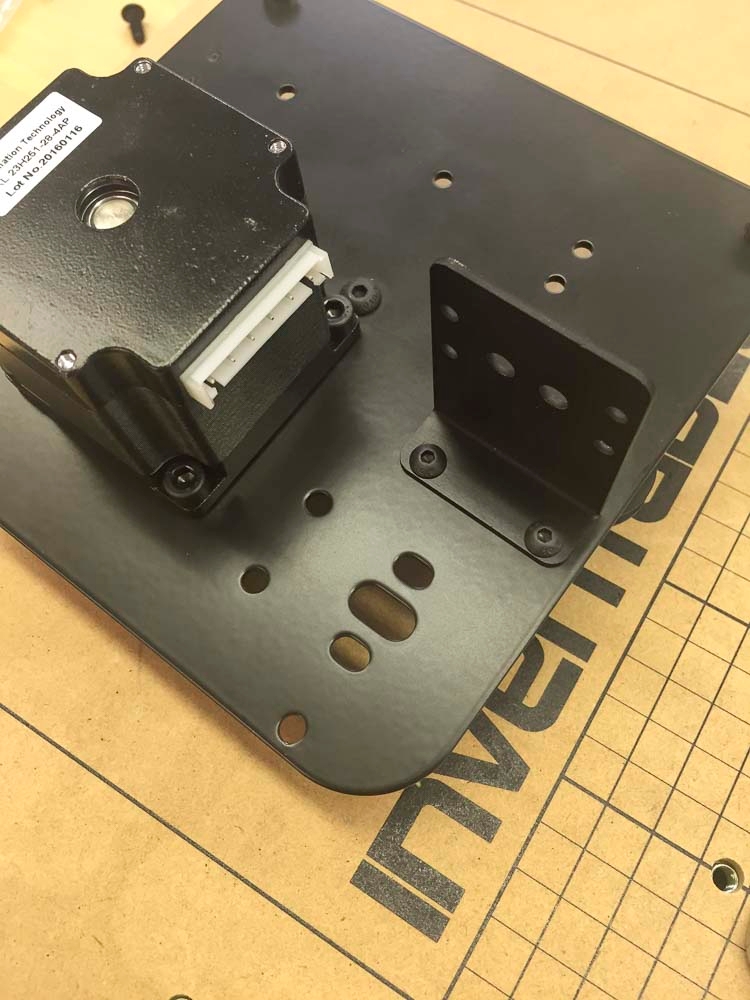

First, position the motor hub in the large hole on the gantry plate on the opposite side of the v-wheels and idler pulleys we just installed. Make sure that the white socket for the electrical connection is facing the rear of the gantry plate (it should be facing away from the angled part of the side plate). Note the orientation in the image below.

If you ordered your X-Carve before March 28 2022 you will use M5x16mm screws for the lower 2 stepper motor mounting holes, and M5x20mm screws for the upper 2 stepper motor mounting holes.

Insert the socket-head cap screws through the stepper motor holes and side plate, then thread on M5 nylon lock nuts to each. See image below.

Note: installing the M5x16 screws on the bottom may be a bit more difficult due to proximity of the idler pulleys. Flip the assembly over so that it is resting on the back side of the motor.

From this position, you can take an 8mm wrench and hold the nylon lock nut in place while you thread the socket head screw from the bottom.

Loosely tighten each bolt with a 4mm hex wrench, holding the nut with an 8mm wrench. Go back and secure each bolt until snug.

Repeat this process for the other side plate. You should now have two mirrored plates that look like this:

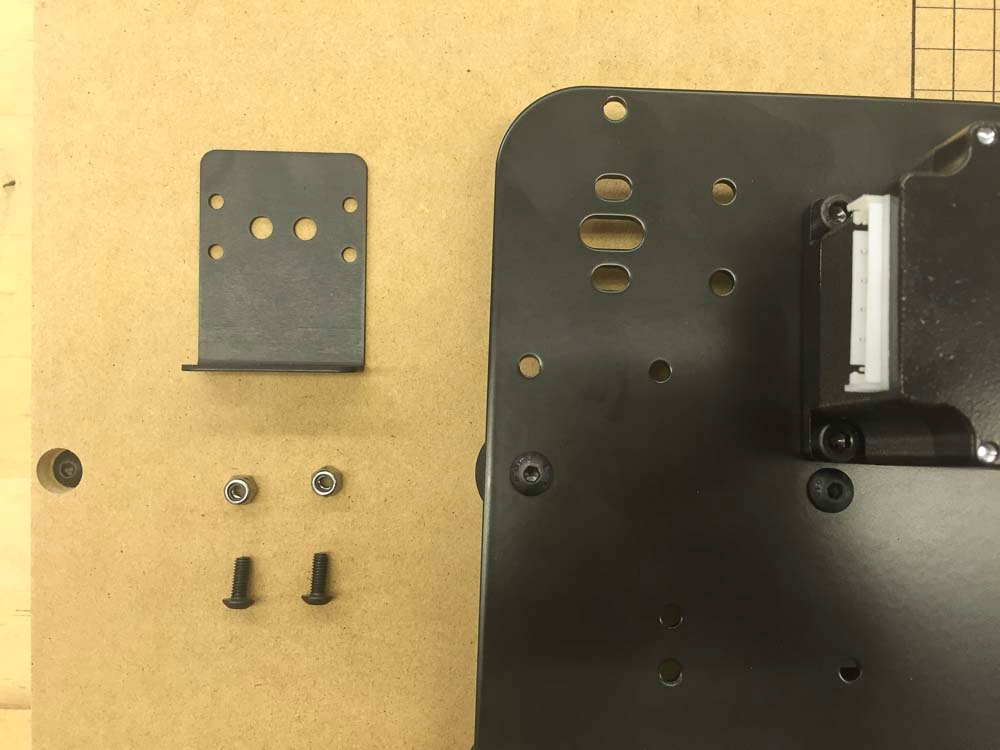

Drag Chain Bracket (Left Plate Only)

Locate 1x drag chain bracket, 2x M4 x 10 button head cap screws and 2x M4 nylon lock nuts. The drag chain brackets and hardware should be included in a bag that is shrink-wrapped to the drag chain links and rails.

1000mm Drag Chain Kit

30527-05

Short Drag Chain Bracket

1

25286-44

Button Head Cap Screw M4 x 10

2

30265-08

Nylon Insert Lock Nut M4

2

Attach Drag Chain Mount on Left Plate

To attach the drag chain mount to the left plate, take 2x M4x10mm screws and put them through their respective holes on the drag chain bracket and plate. Take 2x M4 nylon lock nuts and secure the drag chain bracket with a 7mm wrench and a 2.5mm hex key. Keep in mind that this is for the left plate only, the other drag chain bracket of this type is for the x-carriage.

Last updated

Was this helpful?